Quality

Quality Control

At G-Tech we take Quality Control very seriously, our products are tested to meet Network Rail standards on a continual basis.

During the testing procedure every coper is visually inspected before two further tests are then completed. The Pendulum Slip Test and Surtronic Duo based on 10% of the total batch tested prior to delivery.

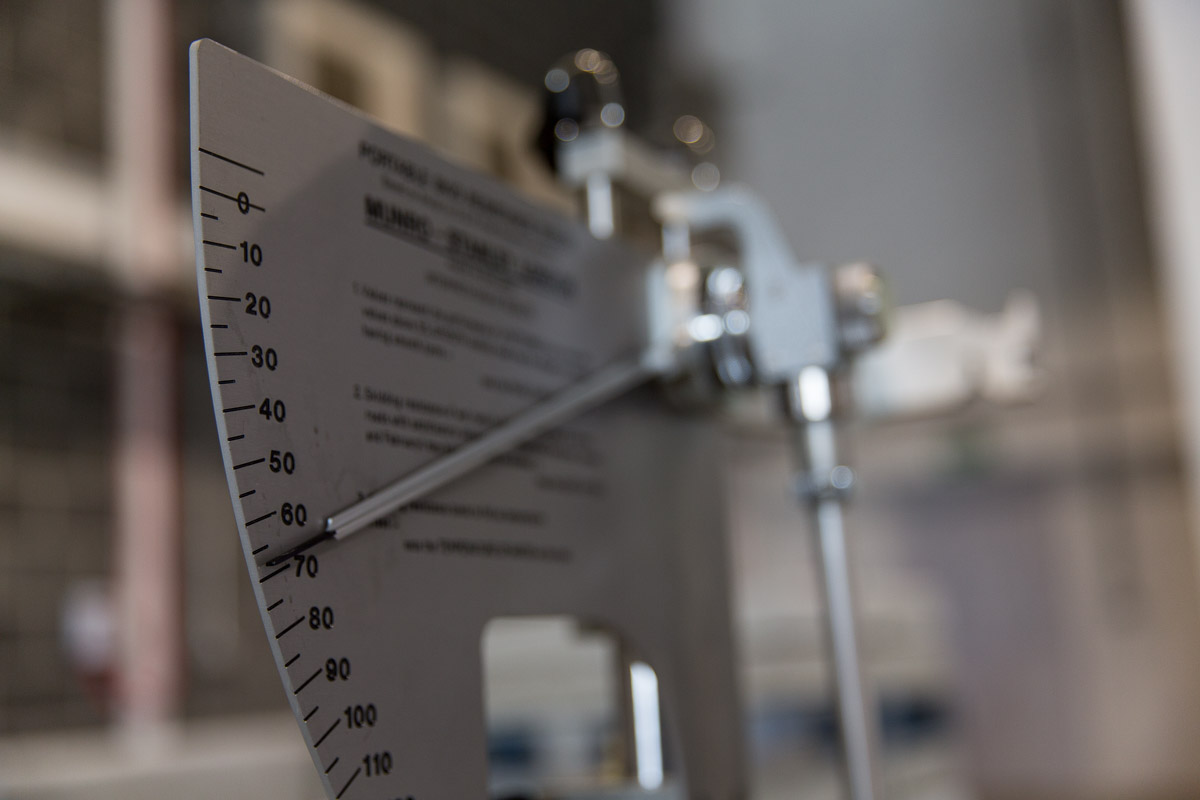

Munro Slip Testing

G-Tech undertake slip resistance testing at in-house facilities and independently. The head of the pendulum is fitted with a 4S Rubber Slider, which has a specific hardness and resilience.

When released from a horizontal position, the pendulum head strikes the sample surface with a constant velocity. The distance travelled by the pendulum after striking the sample, is determined by the friction resistance of the sample surface. The skid resistance values, which, approximately correspond to the co-efficient of friction times 100, are read directly from the clearly engraved scale. The pendulum floor friction test as BSEN13036-4.

Surtronic Duo Surface Finish Testing (Surface Roughness)

Each coper requires a surface roughness test, ensuring strength and durability of the concrete unit. All tests undertaken with a surtronic duo surface roughness testing machine in-house. All coper’s tested must be above the Ra value of 4µm, all G Tech copers conform to Network Rail standard.

Drop Testing

Due to G-Tech producing their own tactiles more tests have been put into place to ensure the durability of all components.

In-house drop testing is undertaken as of Network Rail Standard NR/L3/CIV/030. Any platform component should be able to withstand a 1Kn (102kg) weight being dropped from 1 metre impacting on a 300mm square.